FAQs: Optimize Your Optical Coating Process

How can I speed up the turnaround on coatings? Start with standard specifications rather than creating unique ones requiring the optical coater to reinvent the wheel. Penn Optical Coatings has several hundred standard recipes to choose from, specifically in anti-reflection coatings. Manufacturers should use optics that are in a common diameter for existing tooling. An […]

Optical Coating FAQs:

Optical coating science is not dark magic, but it is a highly specialized, and sometimes high-risk, part of the optical manufacturing process. This series will break it down and provide optics companies and optics buyers with practical considerations for choosing an optical coating partner. Catalog optics companies often need to coat small volumes of varying […]

AR Coatings: What it Means to be ITAR/MIL Certified

ITAR is a set of US government regulations that control the export and import of defense-related technology, designed to ensure that we can control which countries we sell this technology to. In essence, these regulations help ensure that we protect data and technology from unwanted eyes. Anti-reflection coatings are used in a variety of defense […]

Penn Optical Coatings Obtains ISO 9001:2015 Certification to Support Customers’ Quality Systems

Pennsburg, PA (May 1, 2023) — Penn Optical Coatings, an ITAR-registered provider of high-precision standard and custom optical thin film coatings, announced today that it has obtained the ISO 9001:2015 certification. Penn Optical Coatings is now one of a select few ITAR-registered and ISO-certified coaters that can provide robust testing and rigorous quality control, supporting […]

Outsourcing Optical Coatings: Uptick in Demand Anticipated

For decades, even the largest, most vertically integrated companies in the optics and photonics industry have outsourced their coatings. These market leaders recognize that coating is a unique and exacting science. Even more importantly, as a near-final step in the optical manufacturing process, optical coating is a high-risk process with real impact to the finished […]

Anti-Reflection Coatings: Frequently Asked Questions

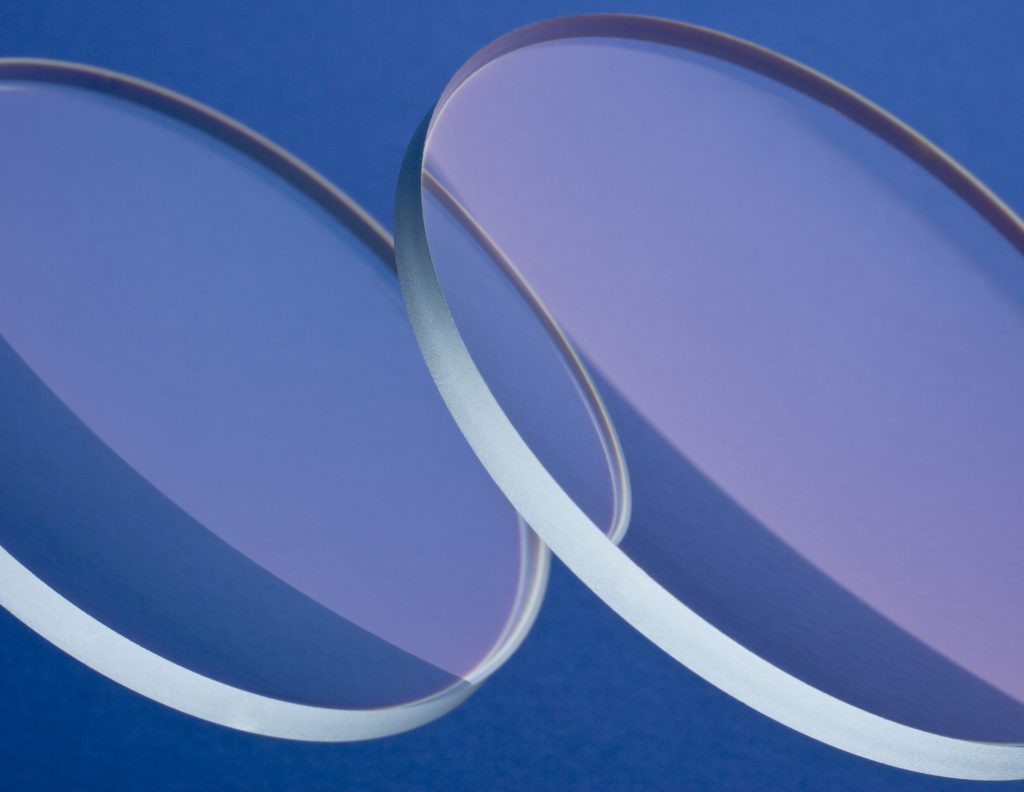

Coatings are critical to optical system performance, and anti-reflection coatings are one of the most common in the industry. Learn more about proper selection, specification and maintenance of AR coatings for glass optics. What is an anti-reflection coating? An anti-reflection (AR) coating is applied to an optical surface to reduce the amount of reflectivity caused […]

Guide to Mirror Coatings

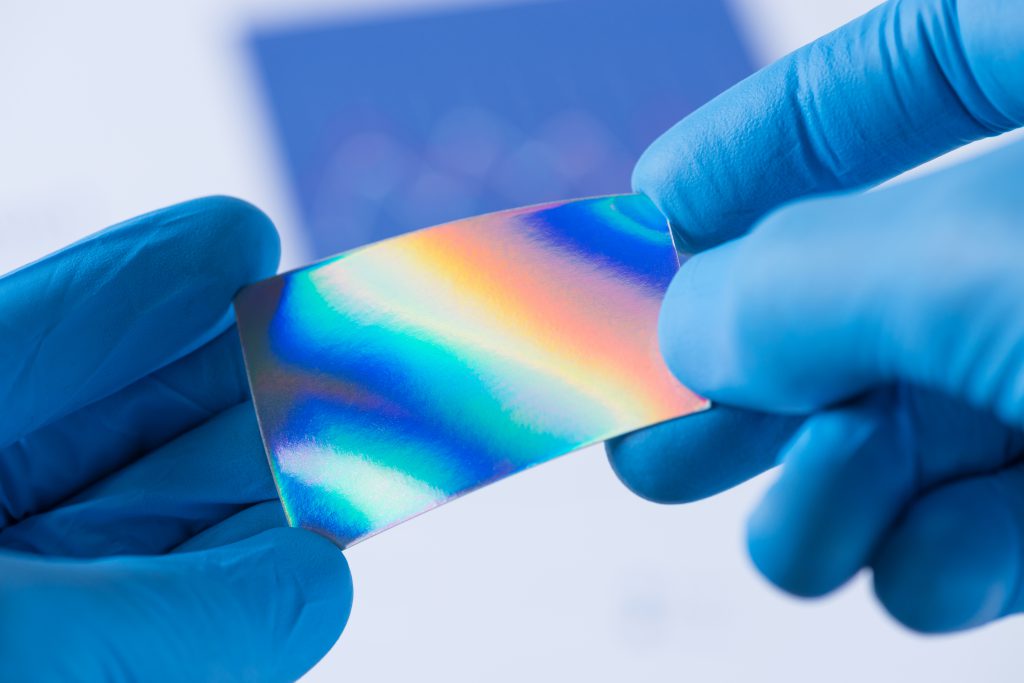

Metallic mirror coatings offer uniform reflectivity over a wide spectral range and minimize reflectivity losses with optimized coating designs and processes. Learn more about the different types of mirror coatings and their advantages.

Advanced AR Coatings Enable Higher Performing Optical Systems

Anti-reflection (AR) thin film coatings are used to optimize desired wavelength(s) or broad spectrum of light transmissions and reduce unwanted surface reflections. AR coatings are the most widely specified coating used in both commercial and defense applications including imaging, solar, auto, semi, medical, life science, telecom, and electronics. The global AR coatings market size was […]

Optimized Coating Designs for Polarizing Optics

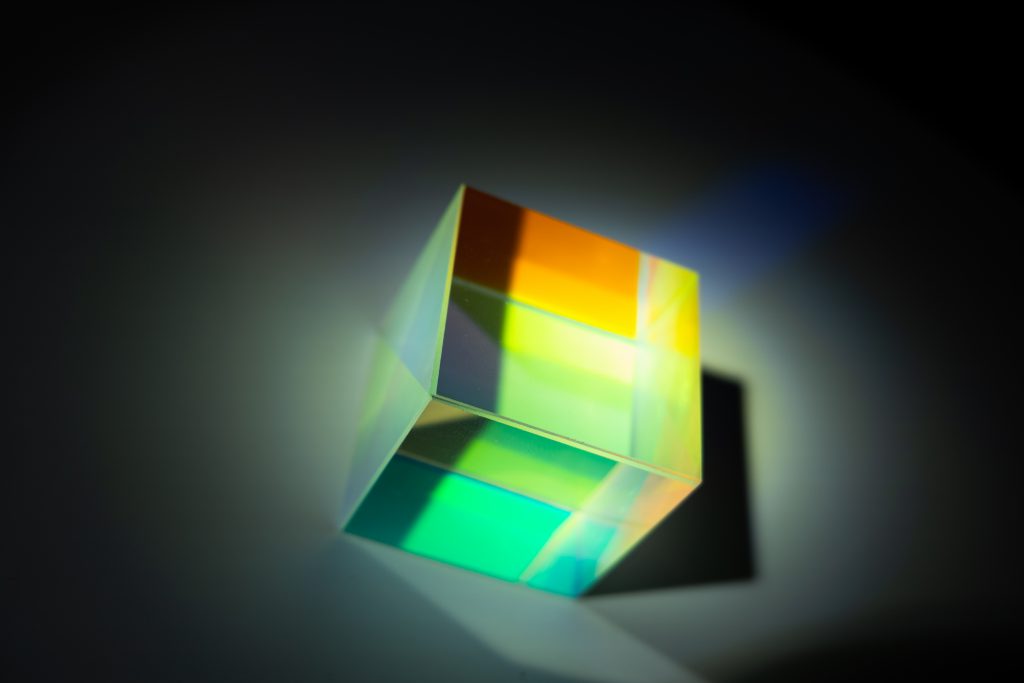

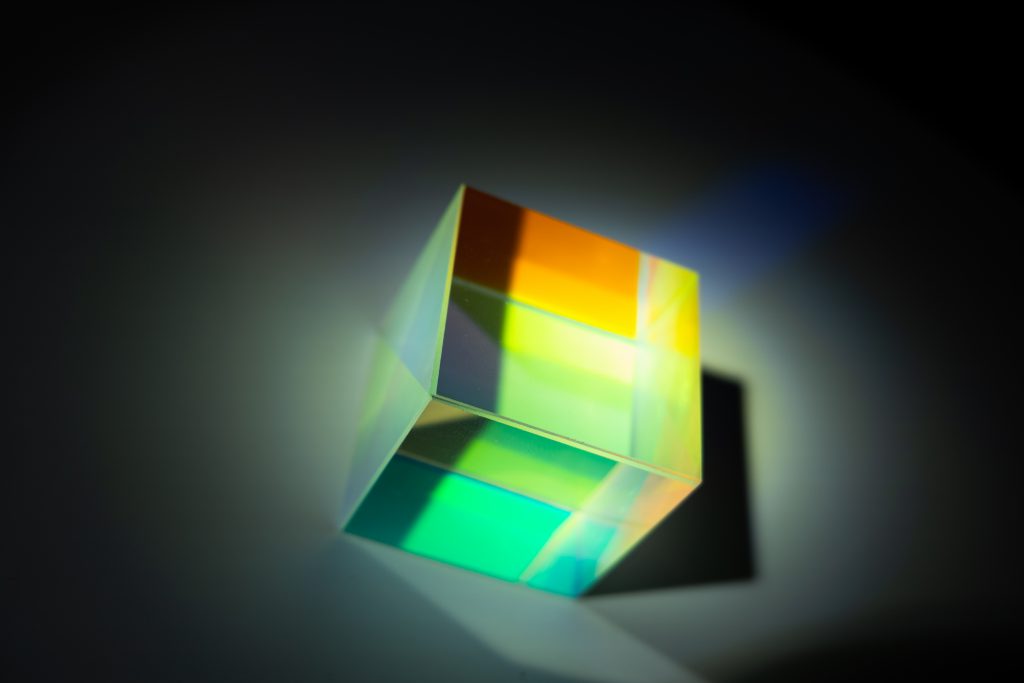

Beamsplitter coatings are normally produced on plate glass or in cube format. The incident beam splits into a partially transmitted beam and a partially reflected beam, where the reflected beam is typically directed 90 degrees from the Incident and transmitted beam. Figure 1 Here we discuss a special group of beam-splitters that use polarization and […]

Optical Coatings Enhance Beam-splitter Performance

Beam-splitters are one of the most widely used components in optical systems. A Beam-splitter is an optical component that divides an incident beam of light into two or more beams by wavelength, polarization, or intensity. A portion of the beam is transmitted, while the other portion is reflected. Cube and plate Beam-splitters are two of […]

Quick-Turn Thin Film Coating Solutions

Quick-Turn Thin Film Coating Solutions Penn Optical Coatings combines precision surface engineering technologies with coating expertise to deposit thin films on multifunctional materials of various applications. Penn Optical Coatings’ products are manufactured in the USA using high quality engineering conditions and expertise to create an excellent range of programs. You might have come across Penn […]

Penn Optical Coatings’ UV-IR Coatings

UV-IR Optical Coatings The most common types of anti-reflection optical coatings are the UV and IR coatings. These coatings are designed to reduce the reflection from surfaces. This is how it works; whenever a ray of light moves from one medium to the other, a portion of it is reflected from the surface. This reflection causes issues […]

High-Quality Beamsplitter Solutions

Penn Optical Coatings Offers High-Quality Beamsplitter Solutions Beamsplitters are used to split light beams into two separate beams with a designated ration. These optical components can also be used to combine two beams into one. They are classified according to their construction as either cube or plate beamsplitters. A standard beamsplitter is designed to split […]